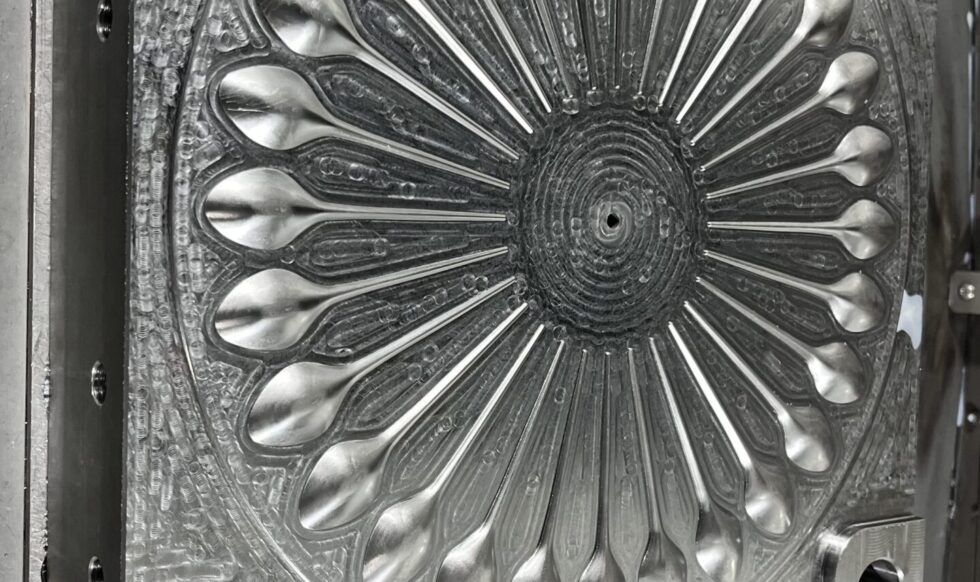

Die and Mould Making

Watch die and mould making is a critical process in the manufacturing of watches. Dies and moulds are precision tools used to shape and form various watch components, such as cases, bands, and dials.

Importance of Watch Die and Mould Making

1. Precision: Dies and moulds are designed to produce watch components with high precision and accuracy.

2. Consistency: They ensure consistency in the production of watch components, reducing variations and defects.

3. Efficiency: Dies and moulds enable mass production of watch components, increasing efficiency and reducing costs.

Process of Watch Die and Mould Making

1. Design: The design process involves creating detailed specifications and drawings of the watch component.

2. Material selection: The selection of suitable materials for the die or mould, such as steel or tungsten carbide.

3. Machining: The die or mould is machined using advanced CNC machines or EDM (Electrical Discharge Machining) techniques.

4. Testing: The die or mould is tested for accuracy and precision before being used in production.

Applications of Watch Die and Mould Making

1. Watch cases: Dies and moulds are used to produce watch cases in various shapes, sizes, and materials.

2. Watch bands: They are used to produce watch bands, including leather, metal, or plastic bands.

3. Watch dials: Dies and moulds are used to produce watch dials with intricate designs and patterns.

Benefits of Watch Die and Mould Making

1. High-quality components: Dies and moulds produce high-quality watch components with precise dimensions and finishes.

2. Increased efficiency: They enable mass production of watch components, reducing production time and costs.

3. Customization: Dies and moulds can be designed to produce customized watch components with unique designs and features.